Written by: Jason Swallow

KEY TAKEAWAYS IN THIS ISSUE OF TECHNICAL TOPICS:

- Feeds contaminated with mycotoxins pose a risk to dairy cattle

- Crop year 2022 corn silage was frequently contaminated with mycotoxins

- Mycotoxins mitigation begins with good silage management

- Mycotoxicosis may be prevented with dilution and adsorbents

Molds can be found growing anywhere, from the crops in your fields to the two-week-old leftovers that got shoved into the back of the fridge. The growth of these fungi is supported by a wide range of conditions: temperatures between 50° and 104°F, moisture levels as low as 12%, and a pH range of 4 to 8. Mold growth on feedstuffs can occur at any time from pre-harvest through feeding due to weather extremes, insect damage, and poor storage and feeding practices. Mycotoxins are toxic secondary metabolites produced by mold that result in a multitude of undesirable effects in exposed animals. These metabolites are typically produced under specific conditions or stressors. An example of this is Fusarium molds, which grow abundantly at temperatures between 77° and 86°F without producing toxins, however, at near-freezing temperatures the mold growth decreases, and massive amounts of mycotoxins are produced.

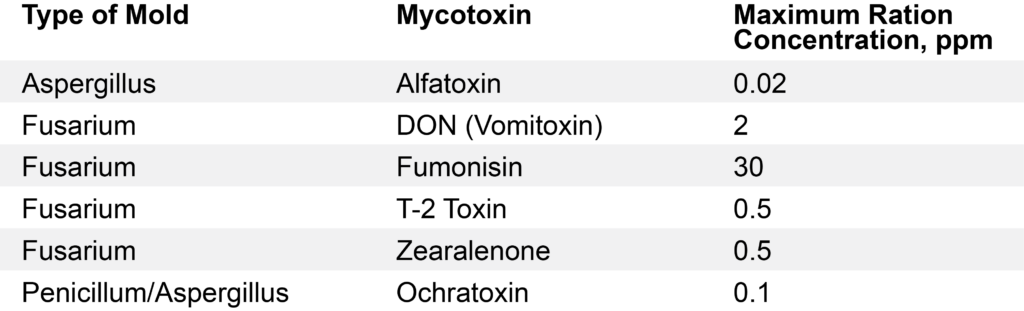

Mycotoxins affect the cow through decreased feed intake, reduced nutrient absorption and impaired metabolism, suppressed immune function, altered microbial growth, as well as altered endocrine and exocrine systems. Hundreds of mycotoxins have been identified, although much more research is needed to determine their negative effects on dairy cattle beyond the handful that the industry understands. Fusarium molds, which are pinkish-white in color, produce the toxins Deoxynivalenol (DON), Zearalenone, T-2 toxin, and Fumonisin. Mycotoxicosis from these toxins can show up in symptoms such as reduced feed intake, reduced milk production, poor conception rates, lower leg swelling, and lethargy.

The chemical structure of Zearalenone is similar to estrogen, producing an estrogenic response in cattle. Ruminants are able to metabolize some toxins in the rumen, reducing their effects, however, in the case of Zearalenone it is mostly converted to alpha-zearalenol, making it up to 10 times more toxic than Zearalenone itself. Symptoms specific to Zearalenone include irregular heat, low conception rates, ovarian cysts, embryonic loss, reproductive tract infections, and an abnormal return to estrus, just to name a few.

The yellowish-green colored Aspergillus mold produces Aflatoxins and Ochratoxins which can suppress the immune system, resulting in increased somatic cell counts, reduced milk production, and liver damage. Aflatoxins are of specific concern in the agricultural industry because they have been shown to be genotoxic, damaging DNA and causing cancer in humans. These toxins have been found in the milk of dairy cattle that have been fed contaminated feed.

Penicillium, a greenish-blue mold, can also produce Ochratoxins along with running the risk of a positive antibiotic milk test.

Mycotoxins are an unavoidable problem in dairy cattle. To date, a way to eliminate mycotoxins completely does not exist, although, there are ways to detect and mitigate them. At the conclusion of every crop year, a few companies marketing mycotoxin adsorbents will test grains and forages from across the United States for mycotoxins. The Alltech® 2022 U.S. Harvest Analysis reported testing 304 samples of corn silage for over 40 different mycotoxins. The results of the report

showed that 100% of the samples contained two or more different mycotoxins with an average of 7.3 mycotoxins per sample. Of the mycotoxins identified, Type B- trichothecenes (DON) were in the highest concentrations, followed by Fumonisin and Zearalenone respectively. The report goes on to state that the presence of DON in early-harvested to late-harvested corn increased over time, which could be explained by the crops being exposed to environmental factors and the corn silage samples from the East and upper Midwest showed a fairly high impact of mycotoxins. This report and others like it are a great tool to be proactive in our mitigation strategies.

The most prevalent masked mycotoxins come from Fusarium molds and cannot be detected by conventional testing due to their modified structure. Glucose molecules attach to the mycotoxin, making it nontoxic and non-detectable. Microbes in the cow consume the glucose molecules, and in the case of DON, return it to its toxic state.

Most commercial forage testing laboratories offer a mycotoxin screening for the six main toxins affecting dairy cattle and many companies marketing mycotoxin adsorbents will provide screenings for free or at a reduced cost. Although mycotoxin screenings are a viable tool to determine what mycotoxins you are dealing with, they may not paint a complete picture of what is affecting your herd. When a sample is gathered for a forage nutrient analysis, you may pull from ten different locations on the face of a bunker, or periodically while the forage is coming out of the silo into the mixer. These samples, mixed, provide us with an accurate nutrient profile of the feeds the cows are eating. Mycotoxins, on the other hand, are not typically throughout the entire face of a bunker or on top of the silo. Ten samples could be acquired, and the mycotoxin could be completely missed. Masked mycotoxins are plant metabolites that co-contaminate many common crops.

The first and most preferred solution in mitigating mycotoxins in your herd is through dilution. I’m sure you have heard the saying, “The solution to pollution is dilution”. Once you have identified the contaminated forage, the type of mycotoxin, and its level, you can reduce the feeding level of that forage below toxic levels. It is important to keep in mind that in feeds containing multiple mycotoxins, it is possible for those toxins to have a synergistic interaction. This means that two or more toxins at levels below the recommended maximum concentration can have an adverse effect equal to or greater than one toxin at a higher level. Bacteria and protozoa in the rumen are capable of detoxifying many of the mycotoxins we encounter. In the case of a high-producing dairy cow and her requirement for an increased passage rate, it is likely that the ability of rumen microflora to denature toxins is limited.

Many different adsorbents exist on the market to help mitigate mycotoxins although none of them are recognized by the FDA for use in dairy cattle. Mycotoxins can be characterized as polar to non-polar molecules, making it imperative that the proper adsorbent is used.

Aflatoxins are considered a polar toxin and bentonites are among the most promising adsorbents, however, not all bentonites are the same. The adsorption can be influenced by the total charge, charge distribution, size of the pores and accessible surface area. Bentonites are also nonspecific and can bind vitamins and trace minerals as well as aflatoxins. Yeast components are natural adsorbents that are extracted from the cell walls of Saccharomyces cerevisiae and consist of mainly α-mannans and β-glucans and contain a diverse mechanism of adsorption against multiple mycotoxins. Mycotoxin deactivators are a purified enzyme that bio transforms toxic metabolites into non-toxic metabolites and have recently been granted approval by the FDA for use in swine and poultry.

Mycotoxins can be mitigated by practicing good silage management. Maintaining proper packing densities and properly covering and sealing storage structures immediately after filling will reduce mold growth in the forage. Maintaining a clean face on a bunker silo and removing 8 inches or more of forage a day will help to minimize spoilage. Stay alert to what mycotoxins are prevalent in your area each harvest and watch for signs of mycotoxicosis in your cattle. Is the manure loose or inconsistent, has feed intake dropped off, has milk production or components decreased, is the somatic cell count elevated, or do the cows just seem lethargic?

These are some of the telltale signs that you have a problem and need to work with your Standard Dairy Consultant to develop a mycotoxin mitigation plan.